We begin in TurboCAD by selecting the "rectangle" icon.Ĭlick the first corner where you want your rectangle to be located and drag and release the left button of your mouse when you have reached the opposite diagonal corner. It is a 6 inch by 8 inch rectangle with a small circle cut out of the middle. Set the zero for your workpiece (in MACH3) Zero the machine coordinates for your Mechmate (in MACH3).ħ. Run the post processor and save your G Code in a tap file (done in your CAM program).Ħ. Open the drawing and specify the correct settings (feed speed, tab locations, etc.)(done in your CAM program).Ĥ. Add the specifications for the raw material from which you will be cutting the object (done in your CAM program).ģ. Draw your object and set the correct layers (done in your CAD program).Ģ.

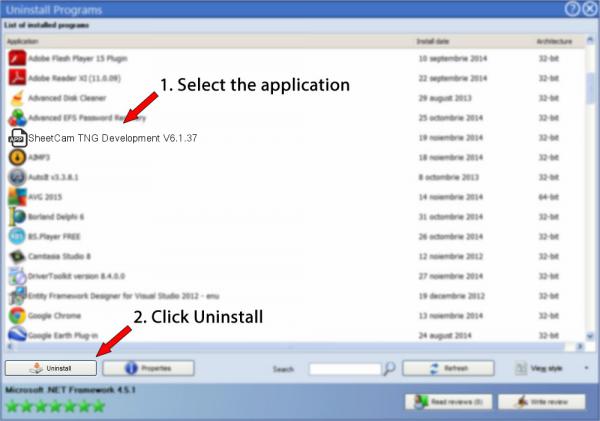

Also, if I have put out incorrect information, please don't hesitate to correct me. If anyone wants to add something, please feel free. It is not intended to be a tutorial and I don't believe Gerald will want his forum tied up with indepth discussions about either of these software packages. The CAM program I use is SheetCAM and it is around $150 give or take a few $$ depending on the current exchange rate.

TurboCAD Deluxe is the CAD program I use and it retails for around $100.

This thread is designed to give the forum members, with no experience in CNC, an idea of what is required to cut out a simple design using relatively inexpensive 2 1/2D(imension) CAD and CAM software.

0 kommentar(er)

0 kommentar(er)